Jim Molnar, Chairman of the Mechanical Association of Railcar Tank Services (MARTS) and industry-expert, Ed Zaharias quickly preview Sponge-Jet Robotic tank car cleaning technology along with other industry updates in the latest issue of JPCL. The article notes “encapsulated media blasting” aka Sponge Blasting technology as a way to increase productivity in rail coatings and lining facilities. Both Sponge Media™ abrasives and the Robotica™ tankcar robot are highlighted.

Read more >Sponge-Jet

Recent Posts

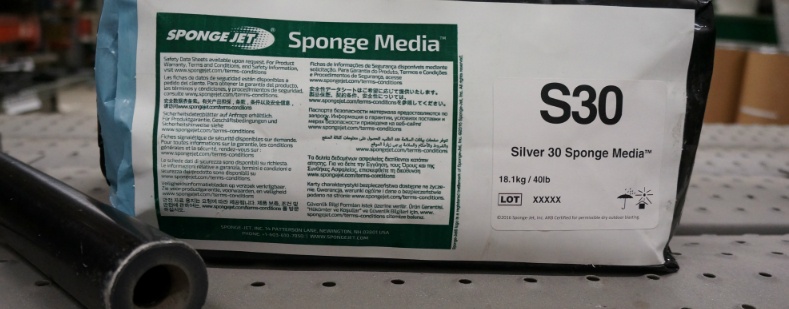

The new labeling system translates important product information in 15 languages, providing access/locations to Safety Data Sheets (SDS), safety information, and terms and conditions.

Read more >

Time is of the essence for any public bridge project. Missing deadlines can be costly to bridge owners, operators and contractors, and ultimately to those who rely on them for daily transportation. For example, 118,600 cars and mass-transit passengers rely on timely passage from Cambridge to Boston, MA (USA) each week over the historic Longfellow Bridge. In the summer of 2013, the clock started on a $255 million project to replace structural elements and restore the bridge’s historical character.

Read more >

Sponge-Jet’s abrasive blasting process is unique in that it can be used in areas where traditional abrasive blasting would quickly be ruled out. Power generation, oil and gas, and other industries have embraced the use of blasting with Sponge Media™ abrasives for its ability to achieve high-quality surface preparation and consistent anchor profiles in dust prohibitive environments, even in potentially explosive atmospheres – where combustion of flammable liquids, vapors or combustible dusts exist.

Read more >

Sponge-Jet is pleased to have been used as the method of choice for the restoration of the 1906 Baldwin Locomotive Works’ Steam Engine 19. Engine 19 has a notable history including being the only engine manned by an all African-American crew in the Carolinas. Through much of its service life, Engine 19 would transport blue granite and crushed stone throughout the region. The steam engine was first acquired by The Railroad Historical Center, located in Greenwood, SC, in 1970. With recent funding support, its preservation became a priority to the museum.

Read more >

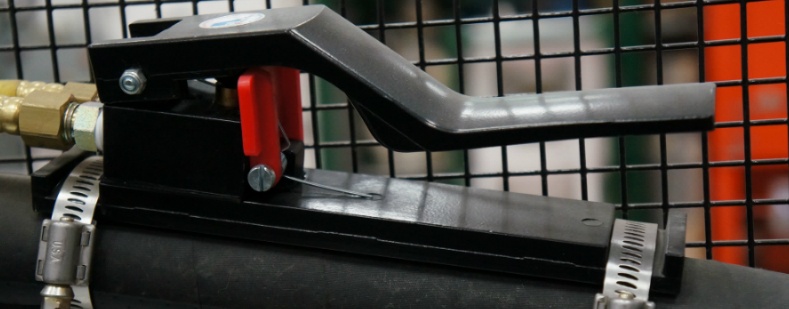

Most abrasive blasting machines have highly technical components with names like control valves, moisture separators, blast pressure regulators. Usually these parts describe what they do. The Deadman trigger system may have a strange name, but it’s vital in stopping the flow of abrasive media and high pressure air in the event the blaster has a safety or medical issue. Abrasive blasting deadman triggers are integral to the safe operation of any Abrasive Blasting system and are mandatory in many countries and are sometimes required by global organizations.

Read more >

Every great business looks to maximize efficiency. Efficiency keeps costs down and increases profit margins. One way to increase the efficiency of workers is through training. This is especially true in the industrial coatings industries (which includes surface preparation). As industry leaders retire, insight and experience can be lost. Training can help combat this loss of wisdom and knowledge. This is why Sponge-Jet built a Global Technology and Training Center at our Newington, NH Headquarters – just an hour north of Boston. Training courses offered at Sponge-Jet range from internationally accredited NACE and SSPC classes to certified training programs on Sponge-Jet abrasive blasting.

Read more >

Exciting news from Sponge-Jet…We are releasing our second model designed to handle the rigors and challenges that paint and blasting contractors face while maintaining the versatility they require.

Read more >

Abrasive Blast Media comes in many different shapes and sizes. The size, shape and also the force with which blasting abrasives are propelled to the surface often determine the profile created during blasting. With few exceptions, most industrial coating projects require a specific anchor profile of the surface or substrate so the new coating can adhere properly. When choosing an abrasive media, remember that both too big of an anchor profile or too small of an anchor profile will cause premature coating failures.

Projects involving granite substrates are a contractor’s most common kind of masonry restoration. Granite is a beautiful, durable stone used on the interior and exterior of buildings, structures, and monuments.It has a Mohs hardness ratings between six and seven and therefore capable of withstanding the demands of everyday life.

Read more >