Whether painting delicate surfaces like tin ceilings, or industrial surfaces such as machinery or roof decking, the quality and longevity of the paint job relies on the surface preparation before coating. On large square footage painting projects, surface prep is often the least considered step, but in reality, it’s the most crucial and plays a key role in the overall success of the paint job. Investing time and effort in this stage is essential to achieve lasting, high-quality results.

Read more >

Concrete has been used in construction for thousands of years, with its earliest known uses for floors, houses, and cisterns in Syria as early as 6500 BC. However, over the last few centuries, the materials used to make concrete have significantly evolved. In 1824, a British bricklayer by the name of Joseph Aspdin evolved the process, creating “Portland Cement." In its modern form, concrete has become one of the most common building materials globally.

Read more >

Choosing the best Sponge Media Feed Unit™ can seem like an intimidating task. Sizes, features, and portability vary between models, but they all do the same overall task of mixing blast media with compressed air for abrasive blasting. Some units like the EX product line are for use in potentially combustable, flammable atmospheres, while other units like the Rasp Xtreme and the 100-HP are optimized for portability.

Read more >

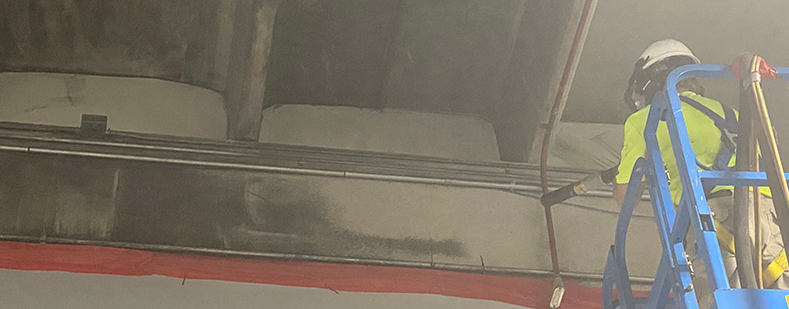

Fires can happen anywhere. While the cause of fires vary, every year thousands of homes, commercial properties, and industrial facilities deal with the cleanup after a blaze. In the aftermath of a fire, structural engineers and insurance companies will work together to determine if a property can be salvaged. In many cases, a fire restoration specialist will work with the owner to resurrect the property from the ashes.

Read more >

When fires occur, the immediate focus should be on preserving the health and safety of those in danger. Fire departments do amazing work saving lives and preventing fire spread throughout buildings and into nearby structures. Despite firefighters’ efforts, buildings often require robust cleaning of smoke, fire, and water damage in the aftermath.

Read more >

Imagine a 50 year old municipal water tank. It’s only been five years since it was last coated, but for some reason the paint is already starting to fail. Rust can be seen spotting all over the tank’s exterior. If we were to do a forensic style analysis on the surface of the tank and the flaking paint chips, we’d most likely see that poor surface preparation is to blame for the failure.

Read more >

Nuclear decommissioning is the process of permanently shutting down the operations of a nuclear power plant. This process must be done safely, and is strictly regulated by government agencies. For example, the Nuclear Regulatory Commission (NRC) is the U.S. agency responsible for making and enforcing the rules, regulations, and procedures that govern nuclear power plant decommissioning. In the United Kingdom, it is the Office of Nuclear Regulation that oversees, regulates and monitors nuclear decommissioning.

Read more >

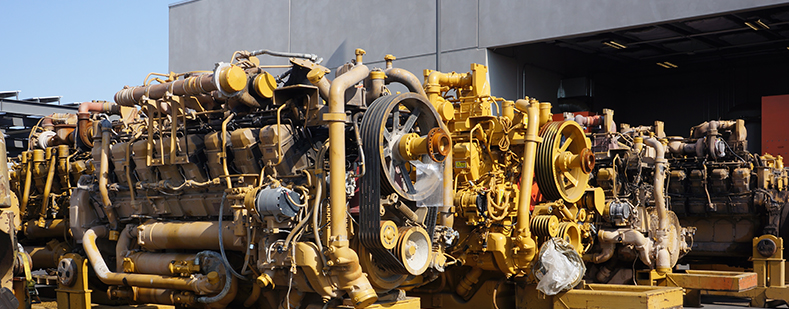

Many advanced Certified Rebuild Centers (CRCs) and Heavy Equipment Refurbishment facilities are turning away from regular abrasive blasting and/or high pressure washing during their re-manufacturing process. Increasingly, these centers are focusing on cleaning the equipment using Sponge-Jet blasting prior to disassembly.

Read more >

Building production capacity at Russia's largest steel and steel-related mining companies doesn’t happen without planning, staging, careful product selection and execution. PAO Severstal announced their plans to add a third blast furnace to the company’s Cherepovets Steel Mill in the Vologda Region, Russia. Corresponding with the install was construction of a wet cleaning scrubber and demister.

Read more >

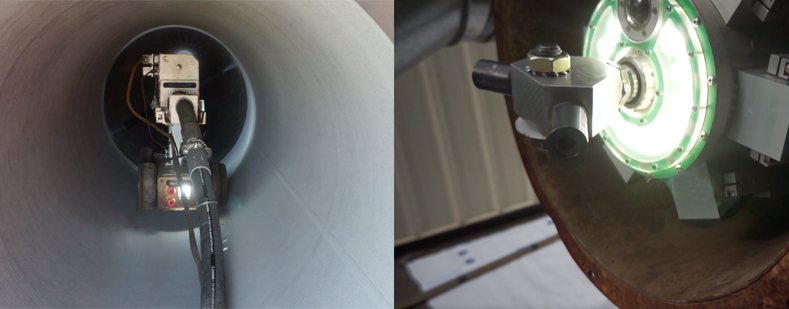

Now more than ever, Contractors are looking for ways to save money, increase worker safety, and reduce waste. For abrasive blasting projects like cleaning tanks, prepping pipe internals, or blasting walls and floors, robotic abrasive blasting is often a better choice than manual blasting.

Read more >