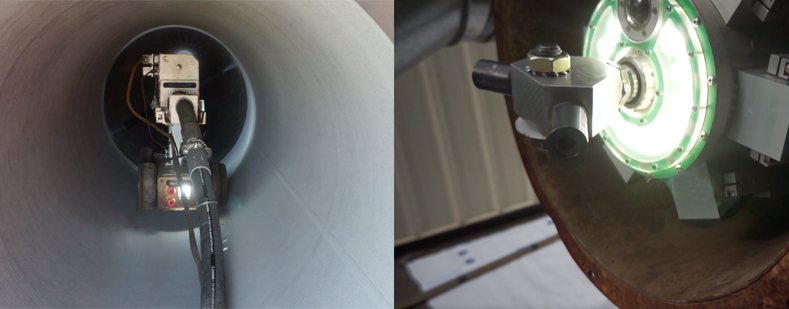

Pipelines are crucial for transporting clean water from treatment plants to cities, businesses, and homes. By maintaining a closed piping system from the source to the faucet, water utilities reduce the risk of water contamination. During the manufacturing of these pipes, proper surface prep must be completed to ensure that they maintain their integrity after coating and installation.

Read more >

Now more than ever, Contractors are looking for ways to save money, increase worker safety, and reduce waste. For abrasive blasting projects like cleaning tanks, prepping pipe internals, or blasting walls and floors, robotic abrasive blasting is often a better choice than manual blasting.

Read more >

Robotic abrasive blasting is a great choice for projects in a wide variety of industries, including oil and gas, water and wastewater, the marine industry, and power generation plants. However, it is important to keep in mind that it is not just the industry itself, but also the application that determines whether robotic abrasive blasting is the right fit for a particular job.

Read more >

Worker safety is the number one priority on all abrasive blasting jobsites. Robotic abrasive blasting is one of the best ways to keep blasters safe while achieving optimal productivity and quality. Overall, robotic abrasive blasting with Sponge Media is a safer alternative to manual blasting in many situations.

Read more >

As contractors and facility managers look for ways to save money, reduce waste, and increase worker safety on abrasive blasting projects, robotic abrasive blasting is becoming more prevalent. Robotic blasting allows for precise control, high productivity rates and reduced abrasive media consumption compared to manual blasting. In addition, robotic abrasive blasting is a safer alternative to manual blasting.

Read more >

Every manufacturing facility and production plant around the world have tanks on their property. These tanks contain a number of different things - some tanks contain liquids like water used for cooling, while others store waste from the manufacturing process. Some tanks hold finished product in the form of liquids or gas. All tanks are built to meet specifications created to prevent tank ruptures. Unfortunately, a tank can perfectly conform to design specifications and still be affected by corrosion and coatings failure. Over time corrosion can lead to structural or tank wall failure creating both an environmental and safety impact.

Read more >

Jim Molnar, Chairman of the Mechanical Association of Railcar Tank Services (MARTS) and industry-expert, Ed Zaharias quickly preview Sponge-Jet Robotic tank car cleaning technology along with other industry updates in the latest issue of JPCL. The article notes “encapsulated media blasting” aka Sponge Blasting technology as a way to increase productivity in rail coatings and lining facilities. Both Sponge Media™ abrasives and the Robotica™ tankcar robot are highlighted.

Read more >