Most abrasive blasting machines have highly technical components with names like control valves, moisture separators, blast pressure regulators. Usually these parts describe what they do. The Deadman trigger system may have a strange name, but it’s vital in stopping the flow of abrasive media and high pressure air in the event the blaster has a safety or medical issue. Abrasive blasting deadman triggers are integral to the safe operation of any Abrasive Blasting system and are mandatory in many countries and are sometimes required by global organizations.

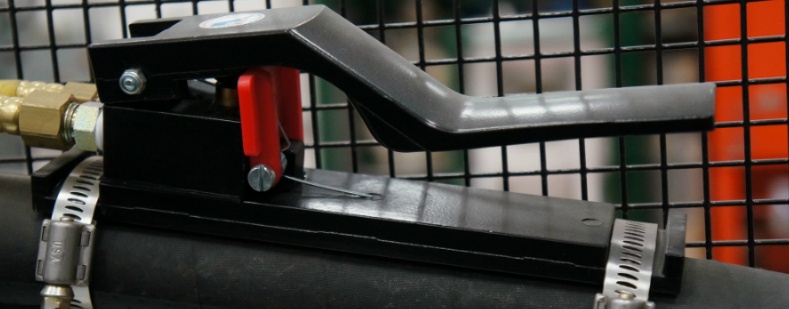

Pneumatic Deadman triggers fall into two common categories: “Positive Bleed” and “Positive Feed.” While similar in design and almost identical visually, the incorrect use of one style on a Pneumatic logic system designed for the other can have serious safety consequences. Care must be taken to identify and install the correct device and to maintain consistent air logic from machine to deadman.

Positive Bleed Deadman

Positive Bleed Deadman Triggers allow a signal of air to exit the Blasting Unit, traverse through one side of a Twinline Set, and then exit a vent hole in the Deadman Trigger Button. When the lever of the Deadman Handle is pressed, the signal of air is prevented from escaping through the vent hole and is redirected through a passageway in the trigger itself. From there the air signal travels through the return-side of the Twinline Set, signaling On/Off Control Components to react, resulting in the flow of abrasive media through the nozzle.

While Positive Bleed triggers have advantages, there are also several disadvantages to this style of safety system. The positive bleed deadman system releases a continuous, audible stream of air. This “leaking” air is ultimately being provided by the compressor, so it produces some level of cost (typically fuel or electricity) even while not blasting. The sound of the leak can mask or obscure other air leaks at the trigger, potentially delaying the blaster from recognizing issues. Lastly, any obstruction in the venting port can cause the unit to start without full movement of the trigger and can even keep the unit in the “on” position longer than expected when released.

Positive Feed Deadman

Positive Feed Deadman Triggers receive the same signal of air as Positive Bleed Deadman Triggers, however they obstruct 100% of the air with the same “on” position of the trigger. The key difference: Positive feed systems drive the action completely. By pressing the trigger, the air is allowed to pass through the device and return to the machine, which commences the blasting.

While both deadman types perform the same vital safety function, Sponge-Jet uses the Positive Feed triggers with its Sponge-Jet Feed Unit™ systems for a number of reasons. Positive Feed Deadman Triggers are less noisy and do not consume or steal air from the blasting process. We believe this deadman type is safer than its counterpart. If supply and return air lines of the Positive Feed Deadman triggers are accidentally reversed, the signal of air will slow dramatically, thus returning to a low enough pressure to signal to the machine to cease blasting.

When using Sponge-Jet abrasive blasting equipment, always use a Positive Feed Deadman Trigger system. Though both systems look similar, they operate in very different ways. If the wrong deadman system is installed with Sponge-Jet equipment, serious issues such as lack of pressure and safety system failure will occur.