Commercial coatings specialists involved in deleading and are yearning for larger contracts might find themselves looking to become more highly certified. Increasingly, large public and private entities (including oil companies, departments of transportation, and public utilities) insist contract bidders possess additional certifications from organizations such as SSPC (The Society for Protective Coatings). SSPC certifies both companies and individuals, verifying contractor organizations with defined knowledge and procedures.

Read more >

Typically applied thick, polyurea and rubber coatings are notoriously hard to remove. Regular abrasive blasting methods are rarely effective in removing these coatings. Abrasives like garnet and coal slag bounce off these surfaces causing them to heat and become gum-like with little removal. This burned residue should not be coated over and would normally require further surface preparation. To avoid these issues, specifiers, contractors and facility owners have three options for polyurea and rubber coating removal.

Read more >

Surface cleanliness and profile are the cornerstones of proper surface preparation, but those standards are not always met. Frequently, metal fabrication projects suffer from bad surface prep. When steel is cut with flame or plasma, the edges that have been cut become harder than the middle part of the steel. This creates challenges for those trying to follow coatings application best practices.

Read more >

Imagine for a moment that ACME Coatings Contractor has recently completed an important water tank exterior coatings project. The job, which involved removing lead-based paint from the 40 meter (135-ft) tall, 3.7-million liter,legged tank, went well from start to finish. The owners are happy, final payment has been rendered, and the project manager is filing the last bit of paperwork when the owner’s representative calls and asks, “Out of curiosity, how can we be sure that ACME didn’t leave lead dust under or around the tank?”

Read more >

B. C. Tilghman: The Father of Sandblasting and Abrasive Nozzles

The process of sandblasting as we know it today started around 1870 with a man named Benjamin Chew Tilghman, who observed abrasive wear on wind-blown desert windows. Tilghman also noticed the effect that high-velocity sand could have on hard material and began designing a machine that could propel sand at speeds much faster than the wind - and could concentrate this flow into a small stream.

Read more >

The historic restoration of Boston's Longfellow Bridge is now complete! The large-scale granite restoration project included onsite blasting by United Stone, as well as dismantling the bridge’s iconic Rockport granite “salt and pepper” towers piece-by-piece, and then transporting them to nearby workyards in Charlestown via barge for offsite restoration. The now pristine towers were reassembled using a mix of modern and historic construction technology. Skilled masons at United Stone were able to clean ornate granite carvings as well as the large granite blocks using the same equipment and media.

Read more >

Shipbuilding and marine repair is frequently heavy, hard industrial work. Manufacturing is loud and can get dirty. In a marine environment like a ship yard (which can include one or more dry docks) this process must occur within close proximity to water, posing unique challenges regarding containment and suppression of dust during the building and repair process.

Read more >

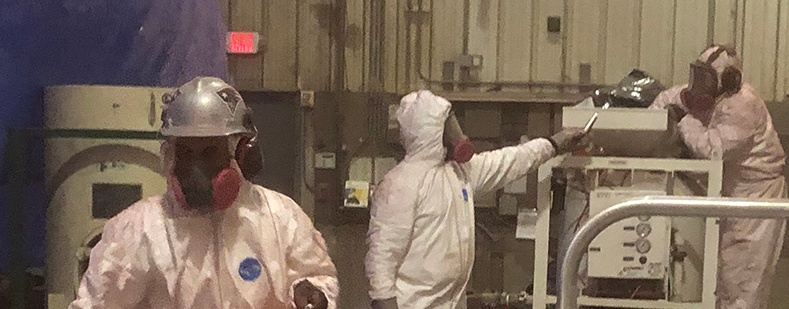

Take a deep breath and consider the following: Every worker required to wear a tight-fitting respirator on the job needs a respirator fit test. In the United States and many other countries, respirator fit tests are law. This law even applies to disposable N95 particulate respirator masks. A respirator fit test, typically conducted in a controlled environment, is markedly different than the quick “seal check” performed whenever a worker puts on a respirator.

Read more >

Those involved in lead paint removal, lead based paint encapsulation, or concerned with lead paint removal costs have likely heard the term “Cradle to Grave,” but not everyone knows what it means in the lead abatement world.

Read more >

The main entrance, an extended portico, leading into the great hall of Ellis Island National Museum of Immigration (NY, USA) required a face lift. Suffering from exposure to the brackish Hudson River salt-spray, the ±625 micron (±25-mil) old coating system was failing and previewing spot corrosion over much of its steel structure.

Read more >