Worker safety is the number one priority on all abrasive blasting jobsites. Robotic abrasive blasting is one of the best ways to keep blasters safe while achieving optimal productivity and quality. Overall, robotic abrasive blasting with Sponge Media is a safer alternative to manual blasting in many situations.

Read more >

Wilson Hall (recently renamed Friedman Hall) is one of the most heavily used buildings on the Brown University campus. The Romanesque-style (circa 1891) structure was built at the bequest of George Francis Wilson and was designed by architects Gould and Angell to expand Brown’s lecture and classroom space.

Read more >

Bronze restoration projects can often prove challenging for asset owners who do not have restoration experience. Due to bronze’s surface characteristics and countless variables that influence them, statues and other bronze items can have a large range in appearance. Before actual restoration begins, owners should consult with conservators/historic preservationists for help with achieving the desired result.

Read more >

The simple answer to this question is a resounding Yes, robotic abrasive blasting is faster than manual abrasive blasting. In order to understand why robotic abrasive blasting is becoming more commonplace in the industry, one must look at the many ways in which it is faster and more efficient – ultimately saving time, money and other resources.

Read more >

As contractors and facility managers look for ways to save money, reduce waste, and increase worker safety on abrasive blasting projects, robotic abrasive blasting is becoming more prevalent. Robotic blasting allows for precise control, high productivity rates and reduced abrasive media consumption compared to manual blasting. In addition, robotic abrasive blasting is a safer alternative to manual blasting.

Read more >

In February 2019, work began on the decommissioning of the Battery Street Tunnel in Seattle, Washington. Completed in 2022, this project was a huge undertaking that included removing the tunnel’s utility and mechanical systems, removing decades of automotive soot buildup from the tunnel, filling the tunnel, and sealing its entrances.

Read more >

In the early hours of a windy Sunday morning, a massive, 10-alarm fire broke out in the downtown area of Waltham, Massachusetts. The fire completely destroyed a condo complex that was under construction, leaving severe soot damage throughout the entire parking garage next door.

Read more >

Abrasive blasting is often a dusty process. When contractors are required to blast near highly sensitive equipment or in areas where air quality is very important, they often need to sacrifice superior surface prep methods or erect extreme containment. At NASA’s Kennedy Space Center in Cape Canaveral, Florida one contractor was tasked with this difficult challenge - providing the highest quality surface prep and low dust blasting with Sponge Media.

Read more >

When rust, corrosion and coating system failure became apparent on pipes in the filter galleries of the Lafayette Utilities Systems (LUS) water treatment plant, a rehabilitation plan was developed. One of the most important aspects of this plan was to prepare the carbon steel surfaces and create the proper anchor profile for the new coating system. Depending on the severity of the rust and corrosion on various pipe sections, the specifications called for either near white metal blast cleaning or commercial blast cleaning.

Read more >

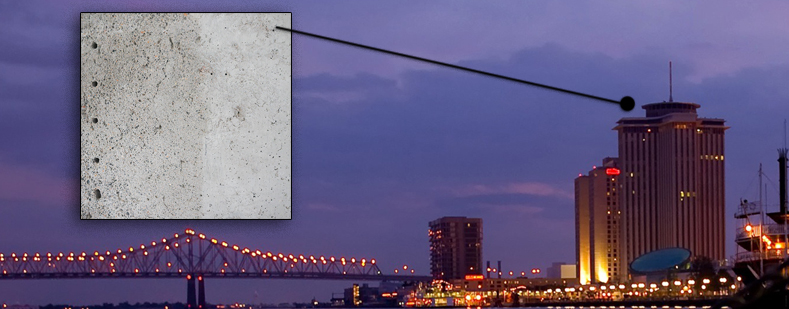

The historic World Trade Center New Orleans is a focal point of the vibrant downtown landscape. Designed by noted architect Edward Durell Stone in the 1960s, the skyscraper is located in the heart of the New Orleans business district and on the Mississippi River. The building formerly housed numerous foreign consulates and was the headquarters for the Port of New Orleans.

Read more >