Corrosion is everywhere - from a speck of rust on a bridge’s bolt to the advanced chemical erosion of a process pump, to blistering paint on a building’s structural steel, fences, and railings. When coatings fail and metal components oxidize, property and infrastructure risk further damage. Corrosion weakens metal from the outside in - untreated metal can rust away completely, leaving behind gaping holes.

Read more >

Every manufacturing facility and production plant around the world have tanks on their property. These tanks contain a number of different things - some tanks contain liquids like water used for cooling, while others store waste from the manufacturing process. Some tanks hold finished product in the form of liquids or gas. All tanks are built to meet specifications created to prevent tank ruptures. Unfortunately, a tank can perfectly conform to design specifications and still be affected by corrosion and coatings failure. Over time corrosion can lead to structural or tank wall failure creating both an environmental and safety impact.

Read more >

Due to concrete’s versatility and cost compared to solid rock, most new building construction includes the use of concrete. Concrete is a technology as old as the Roman Empire, but has evolved to include finishes that can now be used in place of stone countertops or tile floors. When properly installed and maintained, concrete structures can last a very long time.

Read more >

Contractors charged with restoring large buildings often have the time consuming task of repairing and/or repainting window frames and casings. Windows in these buildings can be very heavy and fragile, with glass components highly susceptible to chipping or fracturing. Window damage is avoided at all costs, as the glass is very costly to replace and reinstall.

Read more >

If there was a college major for the coating of metal substrates, the first class would be Surface Preparation 101. The main theme would be maximizing coating adhesion…and to do this, a number of criteria would be taught including visual cleanliness, removing invisible contamination (salts/chlorides, oils, grit embedment), and how to create the coating’s required surface profile.

Read more >

It’s a common belief in the industrial and manufacturing industries that all sparks create a hazard. Sparks can represent poor equipment grounding, short circuiting, or friction and collision energy that can be harmful to workers and machinery. Many also believe that all sparks can create an explosion through combustion in an explosive or flammable environment. While sparks can ignite flammable solids, liquids, or gasses, not all sparks possess the energy to cause an explosion.

Read more >

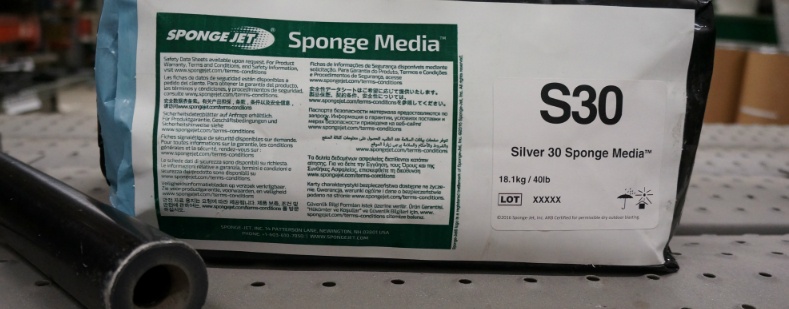

The new labeling system translates important product information in 15 languages, providing access/locations to Safety Data Sheets (SDS), safety information, and terms and conditions.

Read more >

Sponge-Jet’s abrasive blasting process is unique in that it can be used in areas where traditional abrasive blasting would quickly be ruled out. Power generation, oil and gas, and other industries have embraced the use of blasting with Sponge Media™ abrasives for its ability to achieve high-quality surface preparation and consistent anchor profiles in dust prohibitive environments, even in potentially explosive atmospheres – where combustion of flammable liquids, vapors or combustible dusts exist.

Read more >

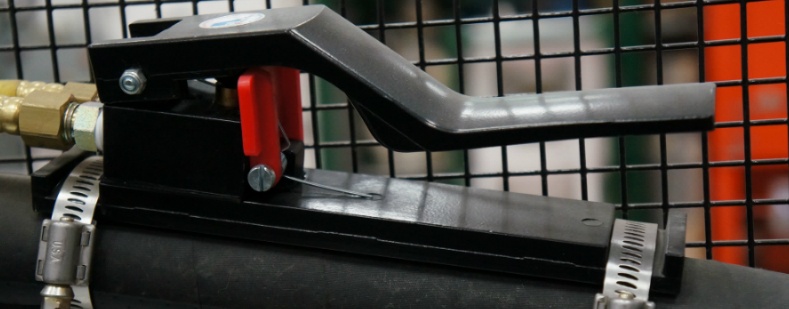

Most abrasive blasting machines have highly technical components with names like control valves, moisture separators, blast pressure regulators. Usually these parts describe what they do. The Deadman trigger system may have a strange name, but it’s vital in stopping the flow of abrasive media and high pressure air in the event the blaster has a safety or medical issue. Abrasive blasting deadman triggers are integral to the safe operation of any Abrasive Blasting system and are mandatory in many countries and are sometimes required by global organizations.

Read more >

If measuring dry film thickness is part of your profession, sign up for this free webinar, which will discuss the latest revision of SSPC-PA 9, “Measurement of Dry Coating Thickness Using Ultrasonic Gages.” This standard describes procedures to measure the thickness of dry, homogeneous coatings applied to concrete, wood, wallboard, plastic, fiber and composite material using commercially available ultrasonic coating thickness gages.

Read more >