When paint starts to peel and bubble, it’s extremely important for the integrity of the asset to remove the old coating and apply a new one. As protective coatings fail, substrate corrosion can accelerate, leading to long term asset damage. If failed coatings and corrosion are not addressed, the damage may not be repairable and the asset may need to be replaced, ultimately costing the owner substantially more money.

Read more >

Imagine for a moment that ACME Coatings Contractor has recently completed an important water tank exterior coatings project. The job, which involved removing lead-based paint from the 40 meter (135-ft) tall, 3.7-million liter,legged tank, went well from start to finish. The owners are happy, final payment has been rendered, and the project manager is filing the last bit of paperwork when the owner’s representative calls and asks, “Out of curiosity, how can we be sure that ACME didn’t leave lead dust under or around the tank?”

Read more >

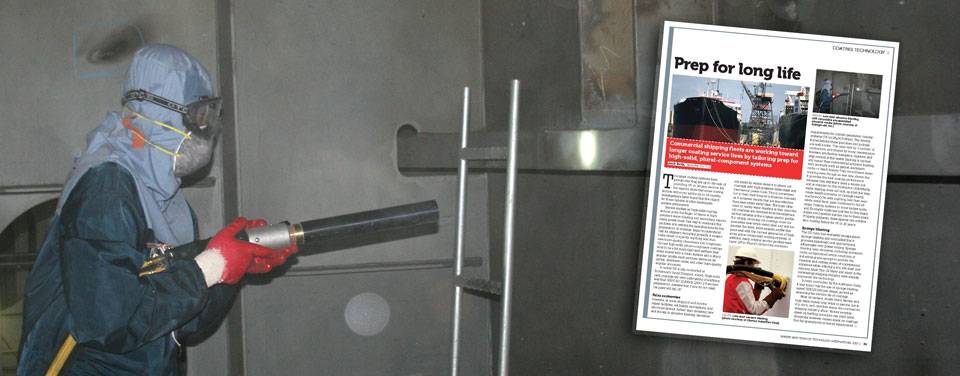

Shipbuilding and marine repair is frequently heavy, hard industrial work. Manufacturing is loud and can get dirty. In a marine environment like a ship yard (which can include one or more dry docks) this process must occur within close proximity to water, posing unique challenges regarding containment and suppression of dust during the building and repair process.

Read more >

The Sponge-Jet Global Training and Technology center has published its 2018 Third-Party class schedule which features a broad range of accredited classes from leading industrial trade associations like the National Association of Corrosion Engineers (NACE International), The Society for Protective Coatings (SSPC) and committee meetings which include the American Society for Testing and Materials (ASTM).

Read more >

On Monday, January 9th, OSHA (Occupational Safety and Health Administration) finalized new beryllium standards for professions commonly exposed to Beryllium. Several are affected including workers in the marine and construction industries. OSHA’s new ruling on Beryllium confirms that at trace levels, beryllium can be harmful. Long-term beryllium exposure can lead to berylliosis, as well as cancer and heart failure. According to author John Emsley, a third of those who contract berylliosis die, leaving the rest permanently disabled.

Read more >

Every great business looks to maximize efficiency. Efficiency keeps costs down and increases profit margins. One way to increase the efficiency of workers is through training. This is especially true in the industrial coatings industries (which includes surface preparation). As industry leaders retire, insight and experience can be lost. Training can help combat this loss of wisdom and knowledge. This is why Sponge-Jet built a Global Technology and Training Center at our Newington, NH Headquarters – just an hour north of Boston. Training courses offered at Sponge-Jet range from internationally accredited NACE and SSPC classes to certified training programs on Sponge-Jet abrasive blasting.

Read more >

The Society of Protective Coatings (SSPC) released its latest Abrasive Specification – SSPC-AB 4, making it the first update since 2000. The AB series of specifications establish proper quality controls and procedures for using Recyclable Encapsulated Abrasive Media during surface preparation. While these standards are not referred to directly in many coating specifications, they are used from within other SSPC documents – most notably SSPC-SP7, SSPC-SP6, SSPC-SP10 and SSPC-SP5. These are perhaps the most widely cited standards for surface preparation worldwide and certainly within the USA. The SP series of standards has always required that abrasives meet an AB quality standard. Before this AB 4 release, exceptions allowed for the use of composite abrasives like Sponge Media, as no AB abrasive quality standards were applicable.

Read more >

Check out this article published by Marine Maintenance Technology International that discusses potential pitfalls when choosing high pressure water and hand-tooling over abrasive blasting. Among them, the author addresses:

Read more >

As it stands today, ordinary abrasive blasting substitutes continue to get hit hard by regulatory bodies around the world as well as by public interest groups due to associated health and environmental risks and impacts.

Read more >Sponge-Jet distributor SAE (Champtoce Sur Loire, France) had a message for their local Corrosion Engineers at the Les Rencontres de la Peinture Anticorrosion exhibition held a few weeks back. You don’t have to compromise abrasive cleanliness levels and profiles in abrasive blasting- prohibited environments – or anywhere else for that matter. No need to use time-consuming hand-tools to create sub-par anchor profiles. You can achieve the highest cleanliness levels and nearly any profile… and even maximize the life of industrial coatings with Sponge-Jet Sponge Media™ abrasives technology. This was the message SA3 was projecting at their most recent corrosion engineering event.

Read more >