When conducting surface preparation work in wastewater treatment plants, there are many factors to consider before blasting ever begins. For example: protecting the pipes, sensitive equipment, and electrical conduit from abrasive dust and ricochet. Not to mention ensuring that the ventilation system is not overwhelmed with abrasive dust.

Read more >Sponge-Jet

Recent Posts

Unexpected jobsite findings when combined with an extremely tight deadline adds a challenging layer to projects that some contractors can’t overcome. This was not the case with Corrosion Control Resources, Inc. (CCR) who arrived on the scene at Arlington Water Utilities Pump Station expecting to hand blast with coal slag, but ended up robotic blasting with Sponge Media.

Read more >

The Miss Ellis Island is one of the boats that carries passengers from the New Jersey-based marina across New York Harbor and onto Ellis Island. Getting ready for the busy summer tourist season includes conducting maintenance on the ferries, and this past year, the Miss Ellis Island was due for some much needed recoating on the walkways and decks.

Read more >

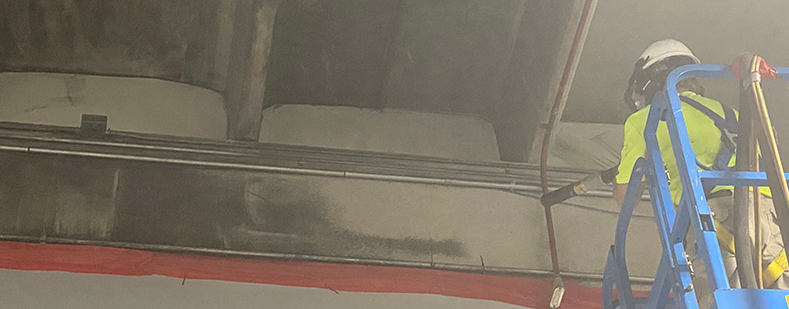

When structural fires occur, they leave behind many hours of cleanup even if the fire doesn’t cause much structural damage. After fires, areas with affected masonry surfaces like concrete must be checked by a structural engineer to ensure entry is safe. Once the area is cleared, the restoration process can begin.

Read more >

When fires occur, the immediate focus should be on preserving the health and safety of those in danger. Fire departments do amazing work saving lives and preventing fire spread throughout buildings and into nearby structures. Despite firefighters’ efforts, buildings often require robust cleaning of smoke, fire, and water damage in the aftermath.

Read more >

The Milwaukee Federal Building and U.S. Courthouse is one of the most recognizable buildings in the historic downtown district of Milwaukee, Wisconsin. Completed in 1899, the Richardsonian Romanesque structure was designated as a Milwaukee City Landmark in 1972 and listed in the National Register of Historic Places the following year.

Read more >

Structures within wastewater treatment plants are exposed to extreme environmental conditions each and every day. Coatings failure in these facilities are common occurrences. If coatings issues are neglected, damage from corrosion can lead to plant shutdowns and costly replacement of assets.

Read more >

Lighthouses are subject to Mother Nature’s harshest conditions: wind, rain, and constant exposure to salt water from the pounding waves of the ocean. It comes as no surprise that these structures and their various components require routine rehabilitation and restoration.

Read more >

Imagine a 50 year old municipal water tank. It’s only been five years since it was last coated, but for some reason the paint is already starting to fail. Rust can be seen spotting all over the tank’s exterior. If we were to do a forensic style analysis on the surface of the tank and the flaking paint chips, we’d most likely see that poor surface preparation is to blame for the failure.

Read more >

When the interiors of five jet fuel tanks at Portsmouth International Airport at Pease needed to be blasted and recoated, contractor L. A. Mangum & Son, Inc.'s confined space blasting and painting experience made them the best choice for the job.

Read more >