Contractors and facility managers alike agree that worker safety is the top priority when working on abrasive blasting job sites.From the depths of underground utility vaults to the interior of storage tanks, examples of confined spaces abound. Found in a wide range of industries and workplaces, each pose a unique risk to those who must enter them.

Read more >

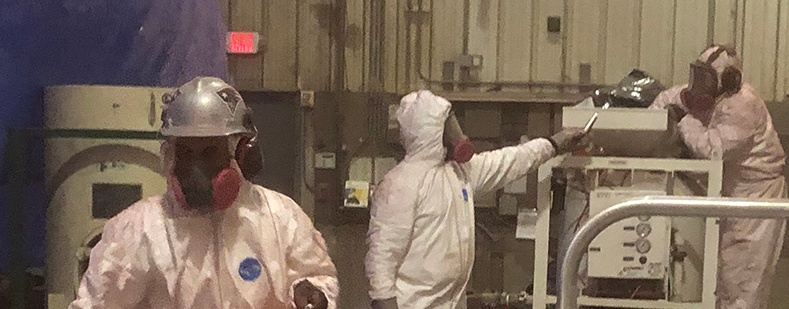

Worker safety is the number one priority on all abrasive blasting jobsites. Robotic abrasive blasting is one of the best ways to keep blasters safe while achieving optimal productivity and quality. Overall, robotic abrasive blasting with Sponge Media is a safer alternative to manual blasting in many situations.

Read more >

Take a deep breath and consider the following: Every worker required to wear a tight-fitting respirator on the job needs a respirator fit test. In the United States and many other countries, respirator fit tests are law. This law even applies to disposable N95 particulate respirator masks. A respirator fit test, typically conducted in a controlled environment, is markedly different than the quick “seal check” performed whenever a worker puts on a respirator.

Read more >

Sandblasting (or abrasive blasting as it’s more properly known) was invented in the late 19th century. The simple process of introducing abrasive into a stream of air and propelling it at high velocity onto a surface has grown with the advancement of technology. Equipment can be as basic or as specialized as desired.

Read more >

In 2017, it was discovered that a major producer of abrasive blasting media had been distributing coal slag contaminated with chrysotile, commonly known as white asbestos. Chrysotile is a known human carcinogen that can be extremely harmful when ingested or inhaled. Asbestos has been found to be a direct contributor to “chronic lung disease as well as lung and other cancers.” OSHA notes, “There is no safe level of asbestos exposure for any type of asbestos fiber.”

Read more >

After 50 years of exposure to the elements, the Frank Lloyd Wright-designed Guggenheim Museum on New York City’s 5th Avenue needed help.

The art museum’s exterior concrete rotunda wall, which corkscrews outward as the building gets taller, was beset by hundreds of cracks ranging from hairlines to those that exposed steel reinforcement bars buried in 5-inch-thick (12.7 cm) concrete. And that’s just what Guggenheim’s team of architects, engineers, and restoration experts could see! Who knew what else lie beneath 12 layers of coatings applied over the decades?

Read more >

OSHA's Final Rule to protect workers from silica is now in effect. Companies that clean, restore, or prepare concrete and stone now have a greater job site responsibility related to respirable crystalline silica that becomes airborne during this process. In their Final Rule, OSHA has reduced the permissible exposure limit (PEL) for respirable crystalline silica to 50 micrograms per cubic meter of air, averaged over an 8-hour shift. To lower airborne silica created by construction processes, OSHA is requiring companies to add engineering controls to concrete, stone and other masonry cleaning and repair processes.

Read more >

Personal protective equipment or PPE is defined by OSHA to be “equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards.” PPE varies based on industrial application – a chemist's PPE would differ from the PPE worn by abrasive blasters.

Read more >

On Monday, January 9th, OSHA (Occupational Safety and Health Administration) finalized new beryllium standards for professions commonly exposed to Beryllium. Several are affected including workers in the marine and construction industries. OSHA’s new ruling on Beryllium confirms that at trace levels, beryllium can be harmful. Long-term beryllium exposure can lead to berylliosis, as well as cancer and heart failure. According to author John Emsley, a third of those who contract berylliosis die, leaving the rest permanently disabled.

Read more >

For over 80 years, industrial professionals have known of the health hazards that are created by sandblasting with silica sand, a once common sandblasting media. When blasting with sand, the particles fragment when they collide with the surface. This dust that is created frequently enters the lungs of the workers doing the blasting and those around them. Once in the lungs, this dust creates a number of ailments, most notably silicosis which can lead to death. Due to these issues, many European countries have banned silica sandblasting - some as early as 1947.

Read more >