Tin ceilings are a popular decorative element in buildings, particularly in older structures. However, restoring a tin ceiling requires careful consideration and attention to detail. These ceilings are typically constructed of thin, delicate metal and can be easily damaged accidentally. Contractors that specialize in restoration should be consulted prior to the beginning of a tin ceiling restoration project.

Read more >

In the USA, some college and university campuses were founded 400 years ago, while globally some universities have been operating for nearly a millennia. Often, these institutions' most recognizable features are the unique visual characteristics of the campus' architecture. Whether these renowned structures are well-preserved originals or renovated within the last 100 years, periodic restoration, renovation, or maintenance projects are essential.

Read more >

Fires can happen anywhere. While the cause of fires vary, every year thousands of homes, commercial properties, and industrial facilities deal with the cleanup after a blaze. In the aftermath of a fire, structural engineers and insurance companies will work together to determine if a property can be salvaged. In many cases, a fire restoration specialist will work with the owner to resurrect the property from the ashes.

Read more >

When paint starts to peel and bubble, it’s extremely important for the integrity of the asset to remove the old coating and apply a new one. As protective coatings fail, substrate corrosion can accelerate, leading to long term asset damage. If failed coatings and corrosion are not addressed, the damage may not be repairable and the asset may need to be replaced, ultimately costing the owner substantially more money.

Read more >

Bronze restoration projects can often prove challenging for asset owners who do not have restoration experience. Due to bronze’s surface characteristics and countless variables that influence them, statues and other bronze items can have a large range in appearance. Before actual restoration begins, owners should consult with conservators/historic preservationists for help with achieving the desired result.

Read more >

Due to concrete’s versatility and cost compared to solid rock, most new building construction includes the use of concrete. Concrete is a technology as old as the Roman Empire, but has evolved to include finishes that can now be used in place of stone countertops or tile floors. When properly installed and maintained, concrete structures can last a very long time.

Read more >

Duluth City Architect, Tari Rayala chose Sponge-Jet as the solution to clean the Duluth City Hall’s high profile, travertine limestone interior walls. Nearly a century of cigarette smoke, “dirtier forms of heating” and oils from visitors bumping the walls, left obscured the creamy fresh look that the stone can deliver. Premium Plant Services and Sponge-Jet are teaming up to complete the cleaning and restoration of the two story project.

Read more >

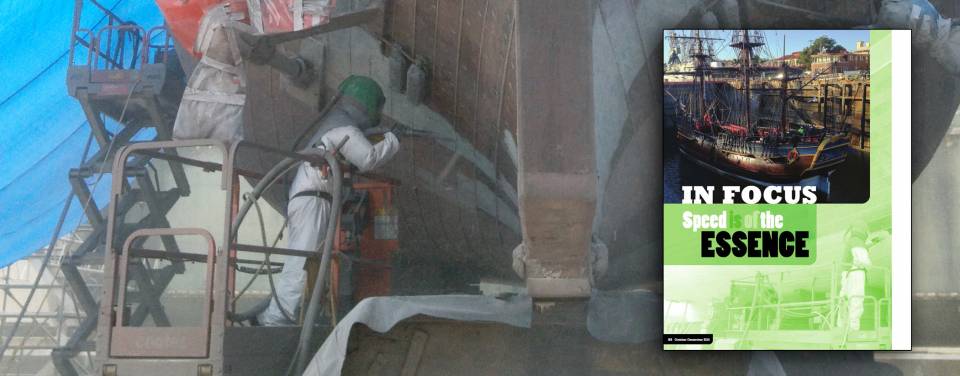

Sponge Media™ abrasives are again used on a historic vessel for its ability to perform coating removal without damage to the substrate. This time it was on the replica HMB Endeavour and thanks to Sponge-Jet Australian distributor Rezitech Services Pty Ltd the project moved quickly enough to sail the Endeavour in time for the 100th Anniversary of the Royal Australian Navy’s Fleet Review.

Read more >

Penn State student, Grant Brown weighs in on how environmental contractor Penoco, Inc. and Sponge-Jet Sponge Media™ abrasives are now protecting the health of Penn State University students, professors, staff and the general public who regularly frequent the Palmer Museum of Art. For more information, click here.

Read more >

Sponge-Jet was recently used to remove paint and corrosion on three centrifugal water pumps. Read this article to see how Sponge-Jet saved the facility service team further dismantling and transport (time/money) of the pumps while protecting nearby equipment from damage and dust. Sponge-Jet Silver 16 Sponge Media™ abrasive was ultimately used to refurbish the pumps in place, creating a 100-micron (4-mil profile) and an Sa2.5 (NACE 2 / SSPC SP-10) finish.

Read more >