Not long ago in Washington D.C. (USA), a large fire broke out in a restaurant during its ongoing remodel. Located along the Chesapeake and Ohio Canal in the bustling neighborhood of Georgetown, the fire left heavy soot (about 20-30 mils) on a variety of different substrates inside the building, including brick, concrete, stone, and wood.

Read more >

Fires can happen anywhere. While the cause of fires vary, every year thousands of homes, commercial properties, and industrial facilities deal with the cleanup after a blaze. In the aftermath of a fire, structural engineers and insurance companies will work together to determine if a property can be salvaged. In many cases, a fire restoration specialist will work with the owner to resurrect the property from the ashes.

Read more >

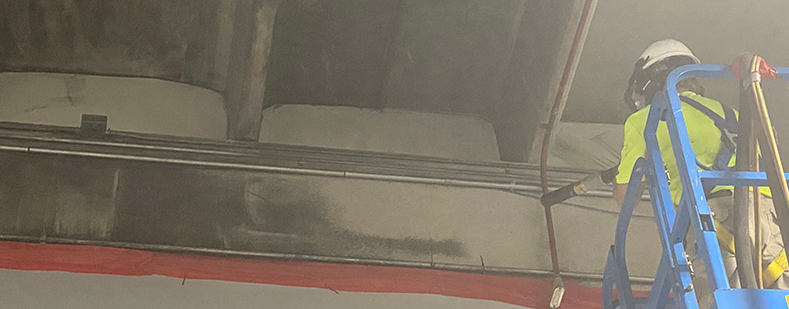

When conducting surface preparation work in wastewater treatment plants, there are many factors to consider before blasting ever begins. For example: protecting the pipes, sensitive equipment, and electrical conduit from abrasive dust and ricochet. Not to mention ensuring that the ventilation system is not overwhelmed with abrasive dust.

Read more >

When fires occur, the immediate focus should be on preserving the health and safety of those in danger. Fire departments do amazing work saving lives and preventing fire spread throughout buildings and into nearby structures. Despite firefighters’ efforts, buildings often require robust cleaning of smoke, fire, and water damage in the aftermath.

Read more >

Imagine a 50 year old municipal water tank. It’s only been five years since it was last coated, but for some reason the paint is already starting to fail. Rust can be seen spotting all over the tank’s exterior. If we were to do a forensic style analysis on the surface of the tank and the flaking paint chips, we’d most likely see that poor surface preparation is to blame for the failure.

Read more >

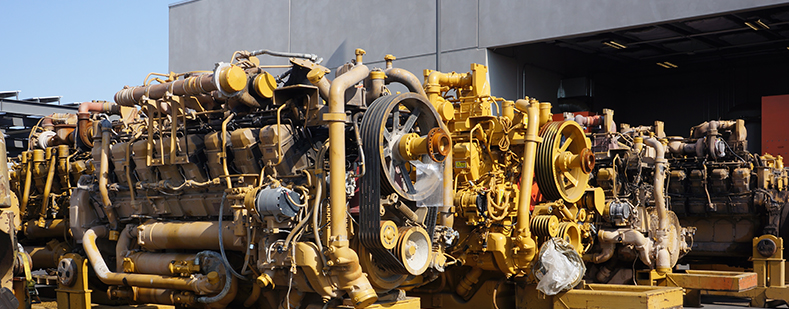

Many advanced Certified Rebuild Centers (CRCs) and Heavy Equipment Refurbishment facilities are turning away from regular abrasive blasting and/or high pressure washing during their re-manufacturing process. Increasingly, these centers are focusing on cleaning the equipment using Sponge-Jet blasting prior to disassembly.

Read more >

In the early hours of a windy Sunday morning, a massive, 10-alarm fire broke out in the downtown area of Waltham, Massachusetts. The fire completely destroyed a condo complex that was under construction, leaving severe soot damage throughout the entire parking garage next door.

Read more >

The historic restoration of Boston's Longfellow Bridge is now complete! The large-scale granite restoration project included onsite blasting by United Stone, as well as dismantling the bridge’s iconic Rockport granite “salt and pepper” towers piece-by-piece, and then transporting them to nearby workyards in Charlestown via barge for offsite restoration. The now pristine towers were reassembled using a mix of modern and historic construction technology. Skilled masons at United Stone were able to clean ornate granite carvings as well as the large granite blocks using the same equipment and media.

Read more >

Surface Preparation (or Surface Prep for short) is the process of cleaning and readying surfaces for new coatings. Due to varying attributes and performance characteristics of the many coating types, surface preparation requirements can also be unique from project to project. As a result, it’s very important to always read the coating specification and all coating technical data sheets.

Read more >

Every manufacturing facility and production plant around the world have tanks on their property. These tanks contain a number of different things - some tanks contain liquids like water used for cooling, while others store waste from the manufacturing process. Some tanks hold finished product in the form of liquids or gas. All tanks are built to meet specifications created to prevent tank ruptures. Unfortunately, a tank can perfectly conform to design specifications and still be affected by corrosion and coatings failure. Over time corrosion can lead to structural or tank wall failure creating both an environmental and safety impact.

Read more >