Working around other trades is one of the most challenging aspects of any surface preparation and coating application job. If a building intends to stay open for business during abrasive blasting, a whole new level of logistical issues come into play. Fortunately, Sponge Media™ blasting eliminated many of the headaches involved with these two common jobsite challenges on a recent parking garage repair and renovation project.

When a 161 space parking garage in Massachusetts needed a major overhaul, APC Services of New England (APCNE) knew that choosing the best surface prep method was vital to the success of the project. The parking garage is connected to a mixed use building that houses banks, law firms, and other businesses that generate a great deal of foot traffic from both employees and customers. The parking garage is also adjacent to smaller commercial buildings that have roof ventilators and intakes. Dust and all emissions from the blast process needed to be contained from a safety and environmental standpoint.

In addition, the abrasive blasting process was to occur while other trades worked on their part of the parking garage restoration project. There were multiple trades working next to, above, and below the areas to be blasted, creating a busy, trade-diverse environment. The APCNE crew had to work around welders cutting and repairing the roof decking, masonry specialists grinding through and repairing concrete, and electricians working on the structure’s wiring. The elimination and containment of dust emissions during the blast process was imperative to keep the other trades safe and the job as a whole on schedule.

This project was featured by CoatingsPro Magazine. In the article found here, APCNE's Project Manager and Estimator, Garrett King said this about the project:

"The customer was so happy and impressed with the color and generally how bright the garage looked."

Garret continues later in the article, "Owners who invest in their buildings, especially during (unplanned breaks), show their tenants that they're not only investing in their infrastructure, but also in the tenants themselves."

Less Than Ideal Substrate Condition

The overall objective of the project was to restore and repaint the parking garage roof decking and structural steel. When APCNE arrived on the scene, the existing steel substrate was not in any condition to receive the new coating system consisting of a Tnemec modified aromatic, a polyurethane primer, and a waterborne acrylic mastic top-coat.

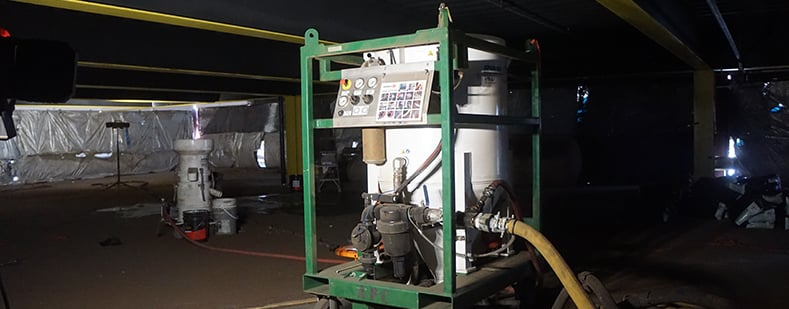

The steel substrate had both adhered and failed coating, as well as Grade A through Grade D rust. Sponge Media blasting was chosen as the surface preparation method to remove corrosion and the failed coating from the existing galvanized roof decking, structural steel beams, fabricated joints, and bolt heads. Surface preparation was also required on the replacement roof deck pieces for proper adhesion of the new coating system.

100,000 square feet (9,300 m²) of steel substrate was prepared using Silver 30 Sponge Media™ to a cleanliness level of SSPC SP-6 - Commercial Blast, with a profile of 3 mils (76μ).

Sponge Media Solves Multiple Issues on the Job

At the stated removal rate, Sponge Media was comparable in cost-per-square-foot (or meter) to coal slag, the other abrasive blasting material considered. Sponge Media does not typically require as much dust suppression and investment to protect adjacent substrates or assets from destructive rebound associated with coal slag blasting, making it a much better fit for the job.

APCNE also considered using vapor blasting to remove the corrosion and existing failed coating. However, this particular method was impractical on this project, as the work was to be done in below freezing winter weather. Sponge Media blasting is not impacted by ambient temperature or humidity, making it an excellent choice in "less than ideal" weather conditions such as sub zero temperatures.

This was not APC's first large Sponge Blasting project. They tackled a parking garage fire restoration project in 2018. To learn more about that project, visit: https://blog.spongejet.com/soot-removal-from-fire-damaged-parking-garage