Located along the main road of Steeleville, Illinois (USA), sits a charming Lutheran Church called St. Mark’s. Surrounded by both homes and businesses in the center of the small town, the Church is a well-known landmark in the community. Prior to a recent renovation, the staff at St Mark's noticed that much of the white paint was peeling off of this decorative ceiling, leaving areas of exposed tin.

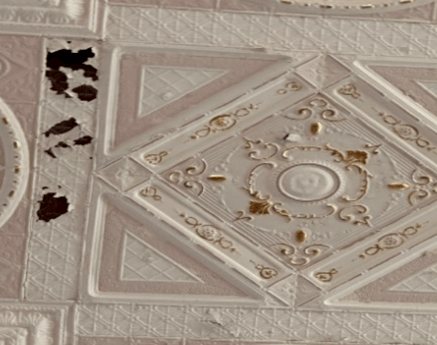

The current sanctuary used by St Mark's Lutheran Church was built in 1897 and enlarged in 1922, making the entire structure over 100 years old. The church's interior adorned with intricate designs integrated into the delicate tin ceiling.

Upon closer inspection, it became apparent that the white paint was delaminating, revealing an old yellow base coat underneath. Additionally, the peeling paint revealed multiple coatings underneath, adding more layers of coatings to the removal process. Recognizing the need for a repaint, the staff understood the importance of detailed surface preparation to achieve a clean finish.

importance of detailed surface preparation to achieve a clean finish.

Tasked with removing the layers of paint off of the ornate tin ceiling, Bare Metal Sandblasting & Restoration originally chose glass abrasives to blast with as their surface preparation method. As the contractors began the surface prep process, they experienced substantial dust generation from the glass abrasive.

The restoration experts at Bare Metal sourced high volume air movers and dust socks to help filter the dusty air, but the amount of airborne particulate was intolerable.

Jeff Moore, owner of Bare Metal Sandblasting & Restoration, said, "Hanging curtains, moving intakes, adding collectors, nothing would solve the problem." Not only was it affecting the quality of their work, but it was also affecting their timeline. Frequent interruptions in order to clear the dust that had accumulated from using glass abrasives meant they were only able to blast around 400ft² per day, putting them way behind schedule.

After multiple days of dust mitigation attempts using a variety of methods, the contractors at Bare Metal Sandblasting & Restoration were not satisfied and realized they needed to take a different approach. They needed an abrasive that would be low-dust while strong enough to remove the multiple layers of coatings and paint off the tin, but still delicate enough to preserve the intricacy of the designs on the centenarian ceiling. Ultimately, they scratched the use of glass abrasives and went with Sponge Media™ instead.

Using Silver 30DG and Silver 60DG, the contractors noticed an immediate difference. Sponge Media was more environmentally friendly, contributing to the safety of both workers and nearby pedestrians alike by minimizing the risk of dust inhalation. Further, thanks to Sponge Media's low-dust and low-ricochet capabilities, the contractors were able to work at a faster pace of 116ft² an hour, with increased visibility during usage. Jeff Moore said, "Dust control using the Sponge Media was a non-issue, the small amount generated was easily handled by a single collector. Productivity with Sponge Media abrasive was higher than the planned productivity with glass abrasive, about a 30% gain."

The switch from glass abrasives to Sponge Media, helped get Bare Metal Sandblasting & Restoration back on schedule. As Cliff Mohling, Regional Manager of Sponge-Jet said, “It was a pleasure to work with the crew at Bare Metal Sandblasting. I'm glad Sponge-Jet was the best fix for their dust problems while preserving St. Mark's historic tin ceilings."

Due to their fantastic work on this project, St Mark’s Lutheran Church is back looking as charming as ever!