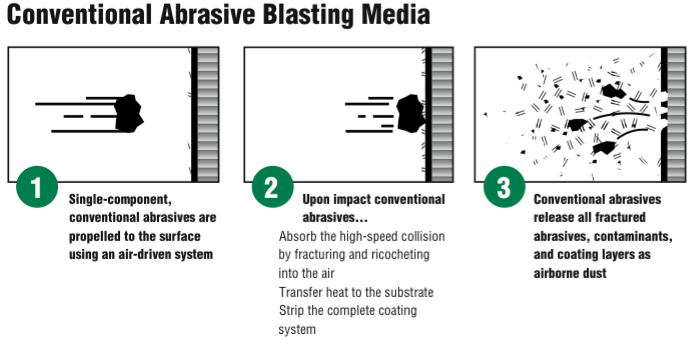

Many abrasive blasting industry products claim to offer low dust, dust free, or dustless blasting. In reality, no blasting media is dust free. “Dustless blasting” is a term commonly used to describe blasting that creates less dust (or fugitive airborne emissions) than traditional blasting methods. Abrasive blasting products prepare surfaces by striking substrates at high velocities using large volumes of compressed air. Sometimes the volume of air alone can generate airborne particles without any blasting being done.

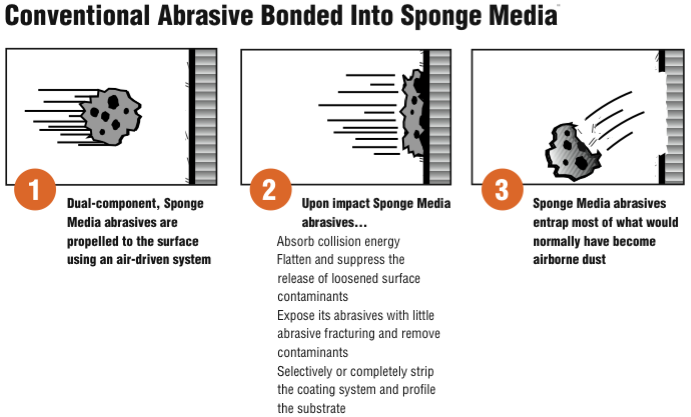

Sponge-Jet generates up to 99% less dust than ordinary abrasive blast media. Sponge-Media™ composite abrasives were developed to entrap particles that would have become airborne during the blasting process. Additionally, Sponge-Media™ abrasives are high-quality, and tend to resist shattering – further reducing fugitive airborne emissions. This is especially helpful when removing lead or pcb-based coatings. As a result, Sponge-Jet media is used frequently on lead abatement projects because of its dust-suppressing properties.

To create the same effect as Sponge-Media, some abrasive blasting products use water and chemical solutions to suppress potential airborne emissions during blasting. While dust can be suppressed with this method, there are additional complexities, time, and resources required to clean, contain, and dispose of the byproducts.

Is 99% less dust than conventional abrasive blasting “dustless blasting?” Sponge-Media™ is as close as it gets to achieve those claims – with no chemical additives or run-off.

For more information refer to the AB-42 Background Document, the Final AP-42 Section and its independent companion Emission Factor Documentation for AP-42 Section 13.2.6