Abrasive blasters who have properly sized air compressors have the best chance for maximizing productivity and efficiency. Contractors and others who blast with mismatched air volume can suffer lost productivity and profits.

An over-sized compressor can lead to higher rental, lease, or purchase costs; higher fuel costs, large job staging, and transportation challenges. An undersized compressor can lead to similar diesel/electric costs, excessive compressor wear, and more importantly lower productivity at the blast nozzle. To avoid both extremes, properly sizing your compressor for blasting can help maximize resources like manpower, energy, staging, and transport.

Properly Sizing an Air Compressor

There are three main components that determine a properly sized air compressor for abrasive blasting.

- Blast Nozzle Size

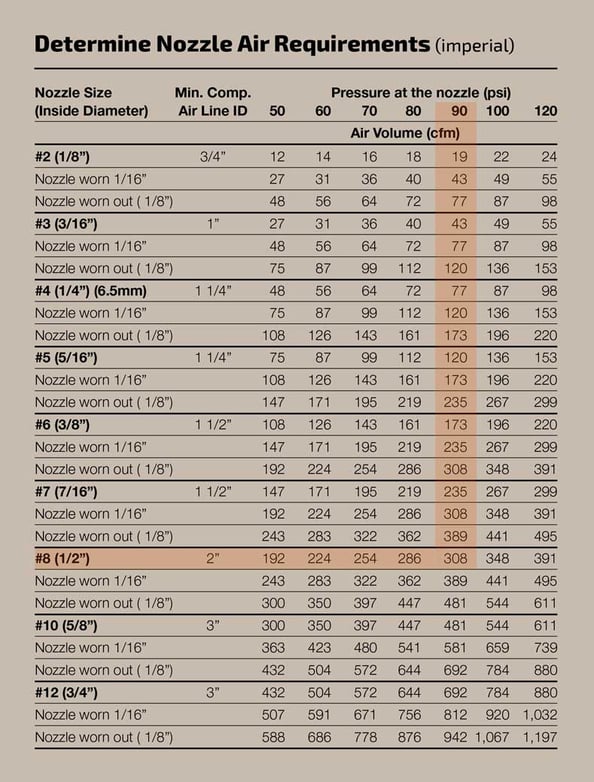

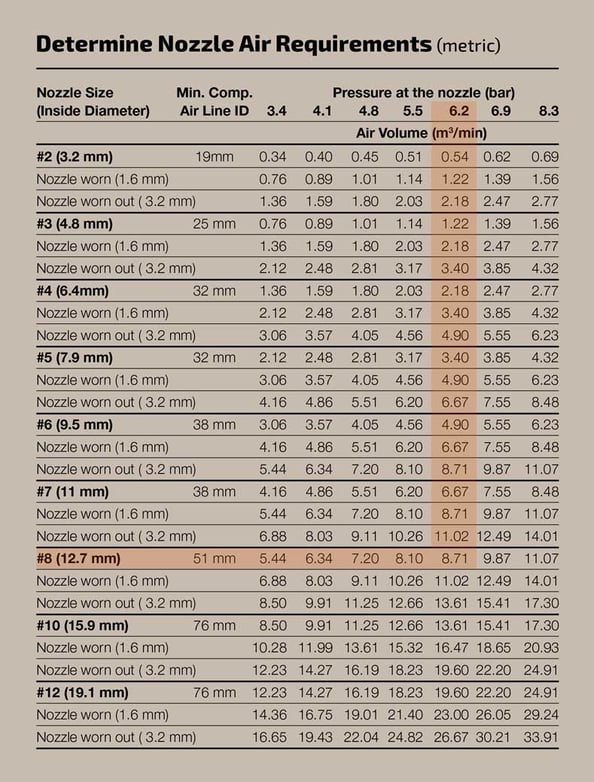

Abrasive blasting nozzles are sized by orifice (Inside Diameter or ID) - and done so in increments 16ths of an inch. The numerator of each 16th of an inch is the nozzle number. For example, a No. 6 nozzle equals a 6/16ths inch diameter orifice; a No. 8 equals an 8/16ths inch diameter orifice. Note that as nozzle orifices change (or wear), so does the air requirement. - Blast Pressure

Units of measurement of pressurized gas used in propelling abrasives to the substrate are expressed as PSI (Pounds per Square Inch) or Bar (the metric unit of pressure). Most abrasive blasting nozzles provide optimized abrasive flow and velocity between 90 and 100 psi (6.2 and 6.9 bar) of blast pressure. - Compressed Air Volume

Compressed air volume is expressed as Cubic Feet per Minute (CFM) or a metric equivalent of Cubic Meters per Minute (m³/min). The two inputs (Blast Nozzle Size and Blast Pressure) help to determine the consistent required volume of compressed air.

While there are many secondary items that require compressed air on jobsites, the nozzle is what drives most of the total requirement. To determine the required compressor size for the nozzle used, see the (imperial/metric) charts below. Start by selecting Nozzle Size, then select the optimal Blast Pressure at the Nozzle. To determine the estimated total CFM requirement, scroll to the intersection of both numbers.

As an example, when using a new No. 8 (1/2 inch) nozzle with an optimal blast pressure of 90psi (6.2bar), use the charts below to determine that the nozzle requires 308cfm (8.7m³/min). In this case, a properly sized air compressor would provide as close to, but not below 308cfm (8.7bar) of compressed air. Note the Minimum Compressed Air Line ID to right of each nozzle size, using compressor air line hose less than the number provided reduces the volume of compressed air. For the No. 8 nozzle, the Minimum Compressed Air Line ID would be 2 inches (50mm).

From this point the compressor size requirement can increase based on pneumatic devices using the same compressor (e.g. blast hoods, moisture separators, other pressure vessel components). Jobsite circumstances, staging and design can also have an impact on compressor sizing (e.g. excessive hose bends, hose lengths, fitting choice). Changes in blast hose internal diameter (ID) and nozzle changes (like Abrasive Blasting Nozzle Wear) can also add to the compressed air requirement.

For additional help with air compressor requirements for Sponge Blasting, click here or contact us at https://www.spongejet.com/contact/