Never Coat a Surface that hasn't been Prepped

When applying a new coating to metal, stone, or other substrates, it’s imperative that the coating has a surface with which to bond. Surface preparation is a blanket term for mechanical or pneumatic methods of treating surfaces to maximize coating life. It is widely accepted that an angular profile created by abrasive blasting is the best method for achieving coating longevity.

This process is easily imagined by considering a mountain climber. Mountain climbers would have a very hard time climbing a sheet of ice because it provides nothing to grab onto - the texture is very smooth, preventing grip. The same mountain climber would prefer climbing a rough surface because he/she has something to hold onto while traversing up the mountain.

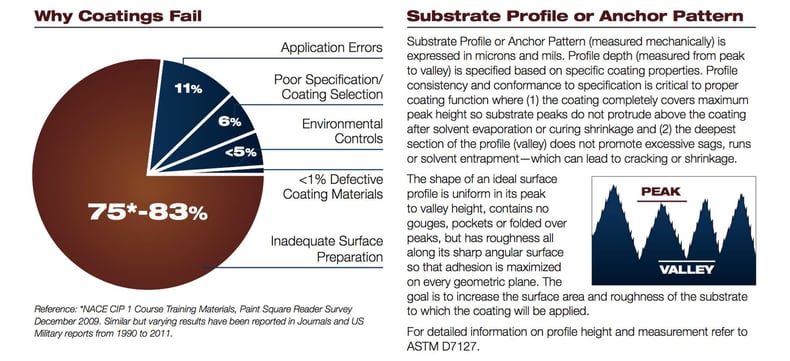

Coatings require the same textured surface. Abrasive blasting provides a uniform anchor profile (a roughness) so every inch of a prepared surface has a specific angular pattern and peak-to-valley depth (or profile). From common two-part epoxy coating systems to polyurea linings, most adhere better to a clean, profiled surface. These “teeth” created from abrasive blasting maximize surface area allowing more coating grip. The result is less premature coating failure, which can be catastrophic to infrastructure like buildings, ships, and bridges, as well as equipment, tanks, pipes, or any other assets susceptible to corrosion.