Contractors and facility managers alike agree that worker safety is the top priority when working on abrasive blasting job sites.From the depths of underground utility vaults to the interior of storage tanks, examples of confined spaces abound. Found in a wide range of industries and workplaces, each pose a unique risk to those who must enter them.

Read more >

Worker safety is the number one priority on all abrasive blasting jobsites. Robotic abrasive blasting is one of the best ways to keep blasters safe while achieving optimal productivity and quality. Overall, robotic abrasive blasting with Sponge Media is a safer alternative to manual blasting in many situations.

Read more >

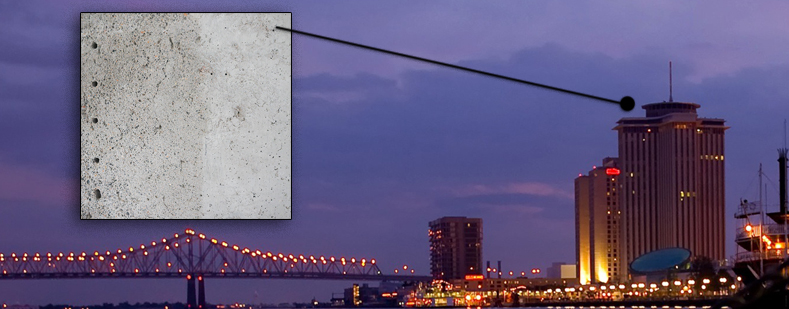

The historic World Trade Center New Orleans is a focal point of the vibrant downtown landscape. Designed by noted architect Edward Durell Stone in the 1960s, the skyscraper is located in the heart of the New Orleans business district and on the Mississippi River. The building formerly housed numerous foreign consulates and was the headquarters for the Port of New Orleans.

Read more >

In 2017, it was discovered that a major producer of abrasive blasting media had been distributing coal slag contaminated with chrysotile, commonly known as white asbestos. Chrysotile is a known human carcinogen that can be extremely harmful when ingested or inhaled. Asbestos has been found to be a direct contributor to “chronic lung disease as well as lung and other cancers.” OSHA notes, “There is no safe level of asbestos exposure for any type of asbestos fiber.”

Read more >

OSHA's Final Rule to protect workers from silica is now in effect. Companies that clean, restore, or prepare concrete and stone now have a greater job site responsibility related to respirable crystalline silica that becomes airborne during this process. In their Final Rule, OSHA has reduced the permissible exposure limit (PEL) for respirable crystalline silica to 50 micrograms per cubic meter of air, averaged over an 8-hour shift. To lower airborne silica created by construction processes, OSHA is requiring companies to add engineering controls to concrete, stone and other masonry cleaning and repair processes.

Read more >

Sandblasting has been used as a cleaning method since the 1870s. Benjamin Tilghman, an American inventor from Pennsylvania conceived of the concept of sandblasting and invented the first sand blasting machine. This first machine and concept paved the way for the use of sand blasting in a multitude of industries, including restoration, oil and gas, and ship building.

Read more >

On Monday, January 9th, OSHA (Occupational Safety and Health Administration) finalized new beryllium standards for professions commonly exposed to Beryllium. Several are affected including workers in the marine and construction industries. OSHA’s new ruling on Beryllium confirms that at trace levels, beryllium can be harmful. Long-term beryllium exposure can lead to berylliosis, as well as cancer and heart failure. According to author John Emsley, a third of those who contract berylliosis die, leaving the rest permanently disabled.

Read more >

Sponge-Jet’s abrasive blasting process is unique in that it can be used in areas where traditional abrasive blasting would quickly be ruled out. Power generation, oil and gas, and other industries have embraced the use of blasting with Sponge Media™ abrasives for its ability to achieve high-quality surface preparation and consistent anchor profiles in dust prohibitive environments, even in potentially explosive atmospheres – where combustion of flammable liquids, vapors or combustible dusts exist.

Read more >

In OSHA’s recent fact sheet, “Protecting Workers from the Hazards of Abrasive Blasting Materials,” abrasive blasting technologies were strongly scrutinized. The fact sheet follows increasing pressure from the general public and industry watchdog groups to include a more holistic approach in protecting those working in and around abrasive blasting operations. The OSHA report discusses health hazards and worker protection methods, stating that, “Employers must protect workers from hazardous dust levels and toxic metals that may be generated from both the blasting material and the underlying substrate and coatings being blasted.”

Read more >

Penn State student, Grant Brown weighs in on how environmental contractor Penoco, Inc. and Sponge-Jet Sponge Media™ abrasives are now protecting the health of Penn State University students, professors, staff and the general public who regularly frequent the Palmer Museum of Art. For more information, click here.

Read more >